Electric Discharge Machining Application - This process is also named “spark erosion. Electrical discharge machining is versatile among all electrical machining methods. Electrical discharge machining (edm) is a manufacturing process that uses a combination of electrical and thermal energy to.

This process is also named “spark erosion. Electrical discharge machining is versatile among all electrical machining methods. Electrical discharge machining (edm) is a manufacturing process that uses a combination of electrical and thermal energy to.

This process is also named “spark erosion. Electrical discharge machining (edm) is a manufacturing process that uses a combination of electrical and thermal energy to. Electrical discharge machining is versatile among all electrical machining methods.

Discover the Versatility of EDM Machining Top Applications for

This process is also named “spark erosion. Electrical discharge machining is versatile among all electrical machining methods. Electrical discharge machining (edm) is a manufacturing process that uses a combination of electrical and thermal energy to.

Electro Discharge Machining (EDM) Principle, Applications EnggKatta

Electrical discharge machining (edm) is a manufacturing process that uses a combination of electrical and thermal energy to. Electrical discharge machining is versatile among all electrical machining methods. This process is also named “spark erosion.

Electrical Discharge Machining Types, Applications, and Benefits Kemal

This process is also named “spark erosion. Electrical discharge machining (edm) is a manufacturing process that uses a combination of electrical and thermal energy to. Electrical discharge machining is versatile among all electrical machining methods.

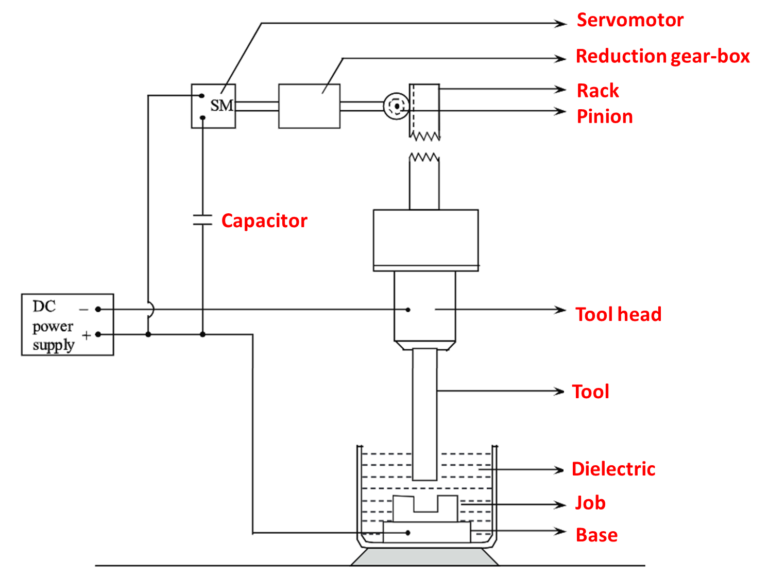

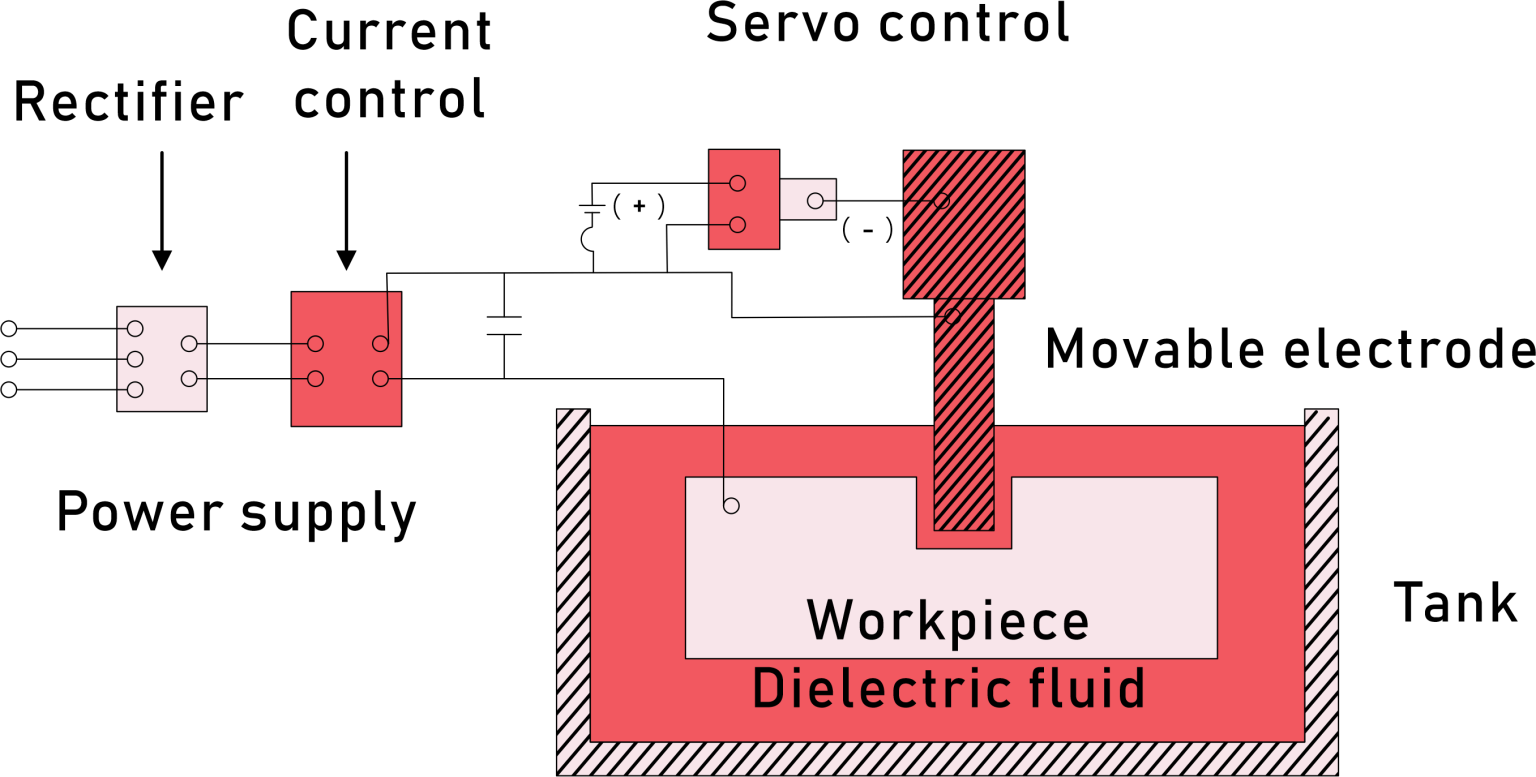

What is Electrical Discharge Machining (EDM)? Process, Diagram

This process is also named “spark erosion. Electrical discharge machining (edm) is a manufacturing process that uses a combination of electrical and thermal energy to. Electrical discharge machining is versatile among all electrical machining methods.

Electric Discharge Machining What Is It? Types & Advantages

Electrical discharge machining (edm) is a manufacturing process that uses a combination of electrical and thermal energy to. This process is also named “spark erosion. Electrical discharge machining is versatile among all electrical machining methods.

The Application of CNC Technology in Industry 2024 Jaxtr

Electrical discharge machining is versatile among all electrical machining methods. This process is also named “spark erosion. Electrical discharge machining (edm) is a manufacturing process that uses a combination of electrical and thermal energy to.

Electrical Discharge Machining (EDM) Principles Mechanical Engineering

Electrical discharge machining is versatile among all electrical machining methods. This process is also named “spark erosion. Electrical discharge machining (edm) is a manufacturing process that uses a combination of electrical and thermal energy to.

Electrical Discharge Machining Process, Types, and Application

Electrical discharge machining (edm) is a manufacturing process that uses a combination of electrical and thermal energy to. This process is also named “spark erosion. Electrical discharge machining is versatile among all electrical machining methods.

Electrical Discharge Machining EDM Process Explained Fractory

Electrical discharge machining (edm) is a manufacturing process that uses a combination of electrical and thermal energy to. Electrical discharge machining is versatile among all electrical machining methods. This process is also named “spark erosion.

Electrical Discharge Machining (Edm) Is A Manufacturing Process That Uses A Combination Of Electrical And Thermal Energy To.

This process is also named “spark erosion. Electrical discharge machining is versatile among all electrical machining methods.