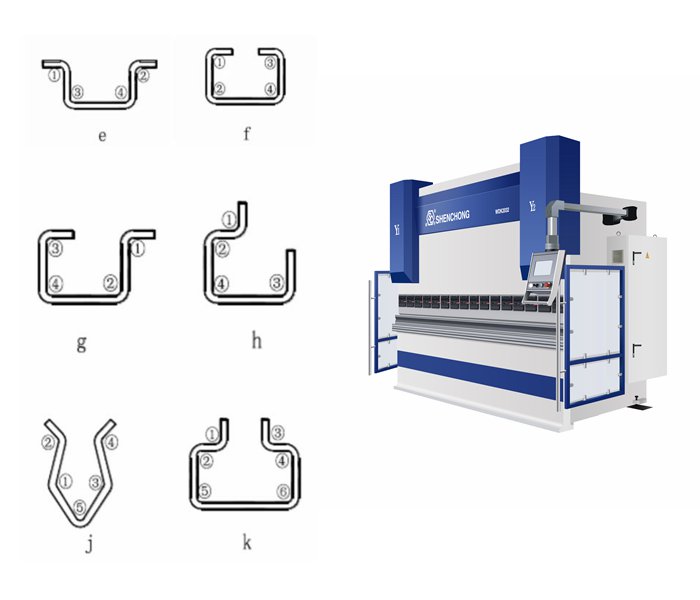

Sheet Metal Bending Rules - If your sheet metal manufacturing designs has. Bending is typically done with a press brake mechanism in a suitable die size. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing.

Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing.

If your sheet metal manufacturing designs has. Bending is typically done with a press brake mechanism in a suitable die size. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing.

Sheet metalbending MPI Industries Limited

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has.

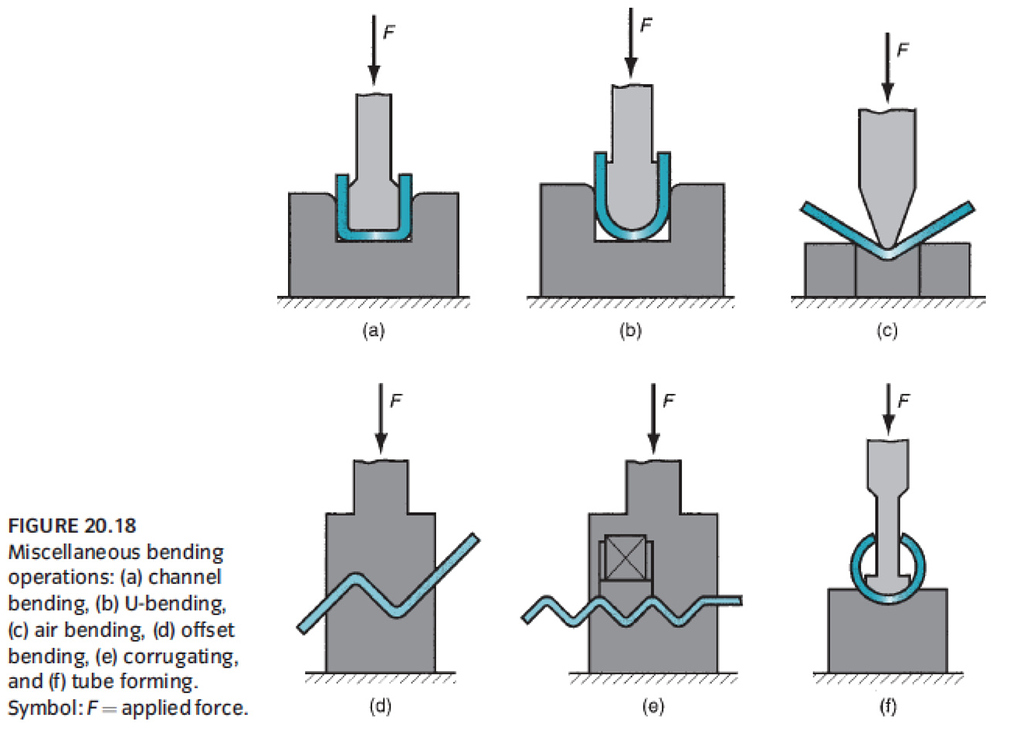

Metal Guidelines Methods of Sheet Metal Bending

If your sheet metal manufacturing designs has. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. Bending is typically done with a press brake mechanism in a suitable die size.

Sheet Metal Bending Techniques

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. If your sheet metal manufacturing designs has. Bending is typically done with a press brake mechanism in a suitable die size.

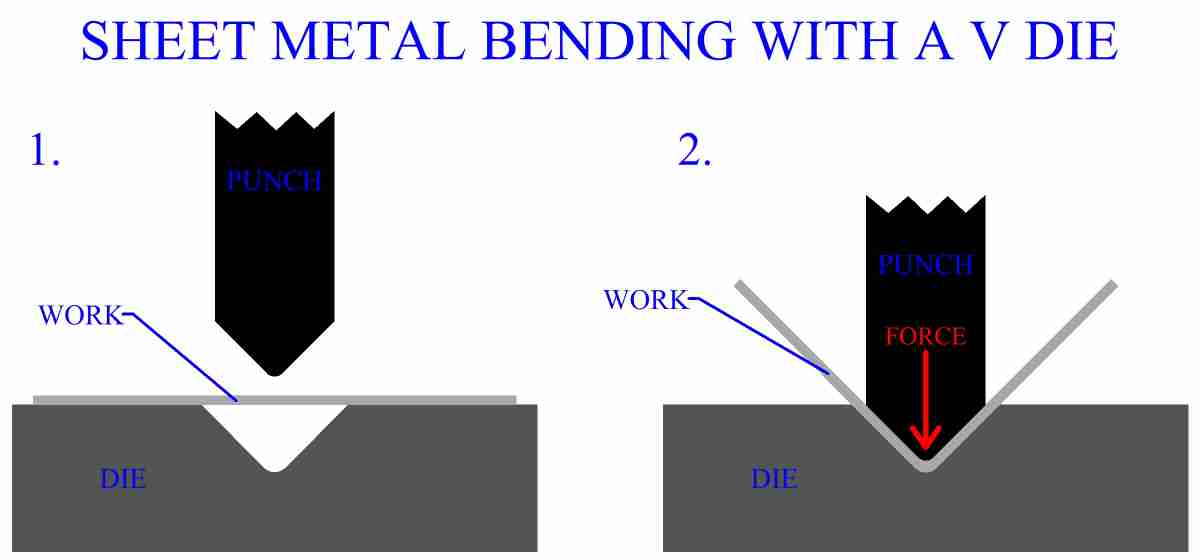

Basics of Sheet Metal Design Consumer Hardware Guide Hardware FYI

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has.

The art of sheet metal bending

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. If your sheet metal manufacturing designs has. Bending is typically done with a press brake mechanism in a suitable die size.

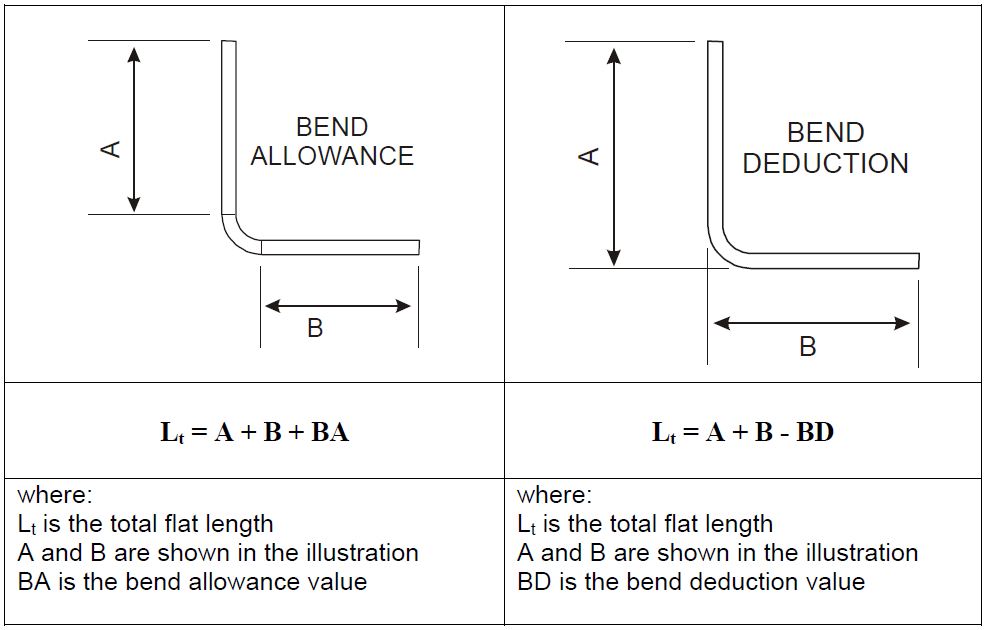

sheet metal bend allowance and deduction

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has.

Richtlinien zum Biegen und Umformen von Blechen CNC

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. If your sheet metal manufacturing designs has. Bending is typically done with a press brake mechanism in a suitable die size.

Common Sheet Metal Fabrication Techniques Meta Fab, Inc.

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has.

Sheet Metal Bending Design Guidelines

If your sheet metal manufacturing designs has. Bending is typically done with a press brake mechanism in a suitable die size. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing.

A Designer’s Guide For Ensuring The Manufacturability Of Sheet Metal

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. Bending is typically done with a press brake mechanism in a suitable die size. If your sheet metal manufacturing designs has.

If Your Sheet Metal Manufacturing Designs Has.

Bending is typically done with a press brake mechanism in a suitable die size. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing.